rugged innovation

INDUSTRIAL

COMPUTING SOLUTIONS

Designing and Manufacturing Hazard-Location Certified Computers and Technology that have been Tested and Proven for the Toughest Environments on Earth.

RUGGED INNOVATION

Designing and Manufacturing Hazard-Location Certified Computers and Technology that have been Tested and Proven for the Toughest Environments on Earth.

Need a Custom Solution?

Schedule a free consultation or product demo call with our engineers today.

Proudly Designed & Built in Canada.

Acura Embedded is a recognized global leader in the HazLoc industry developing ground-breaking customized computing and IOT solutions for some of the worlds leading energy and resource companies.

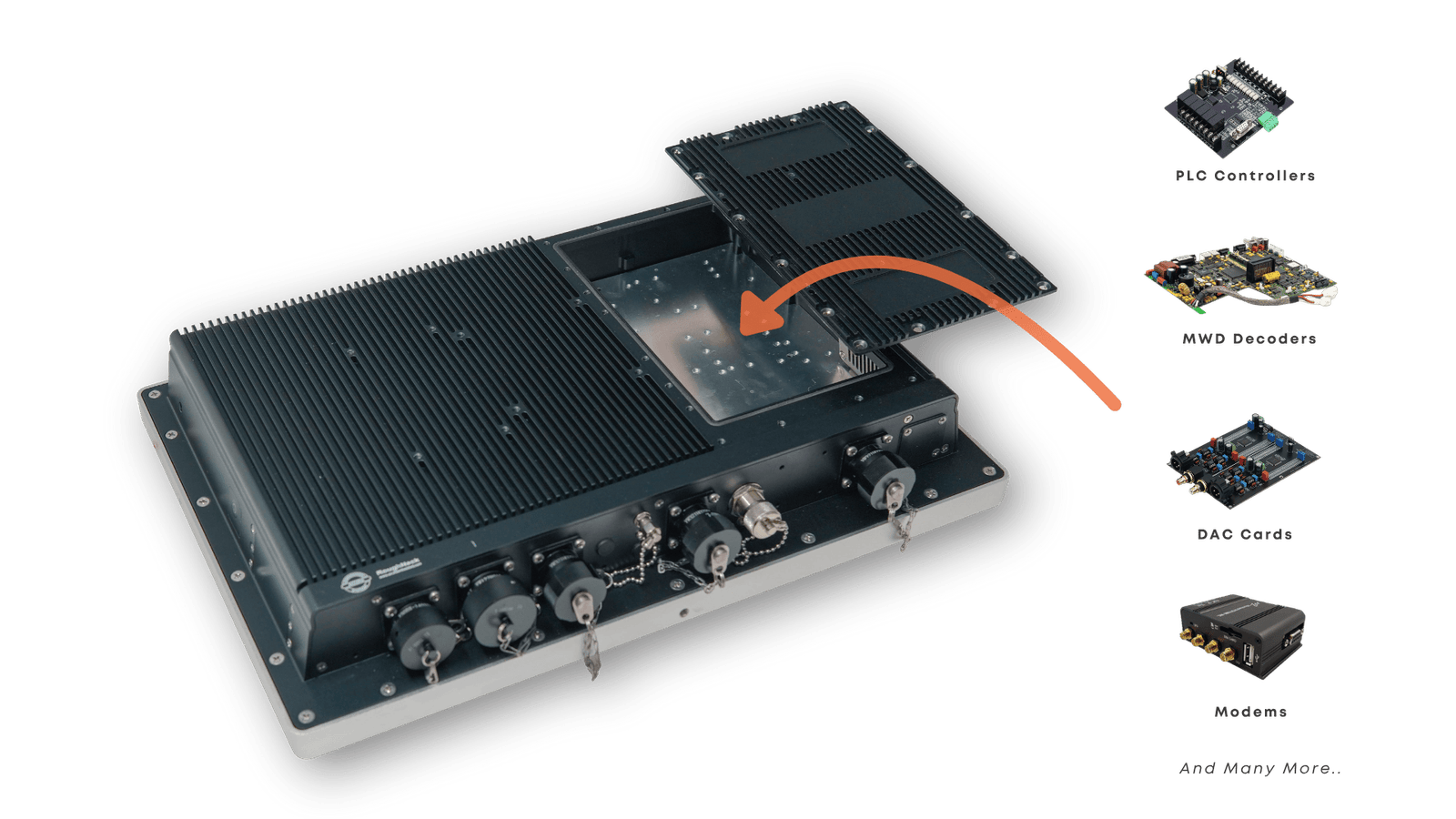

Integrate and Certify Your Tech.

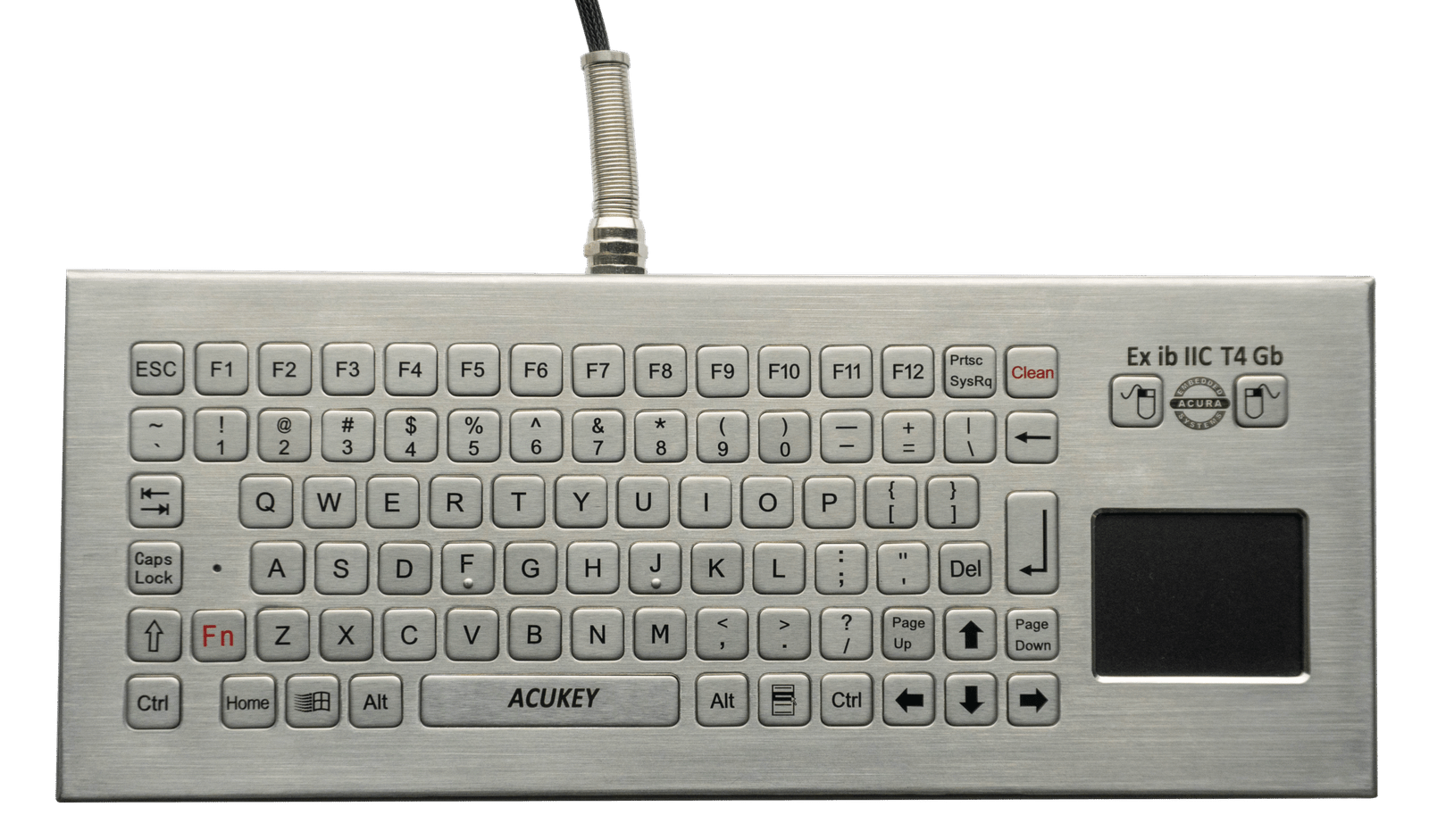

We specialize in developing customized Hazard Location certified hardware. Our team of engineers will work with you to integrate technologies to streamline processes and mitigate costs for your projects.

Reduce Project Operation Costs

Intergrate and Streamline

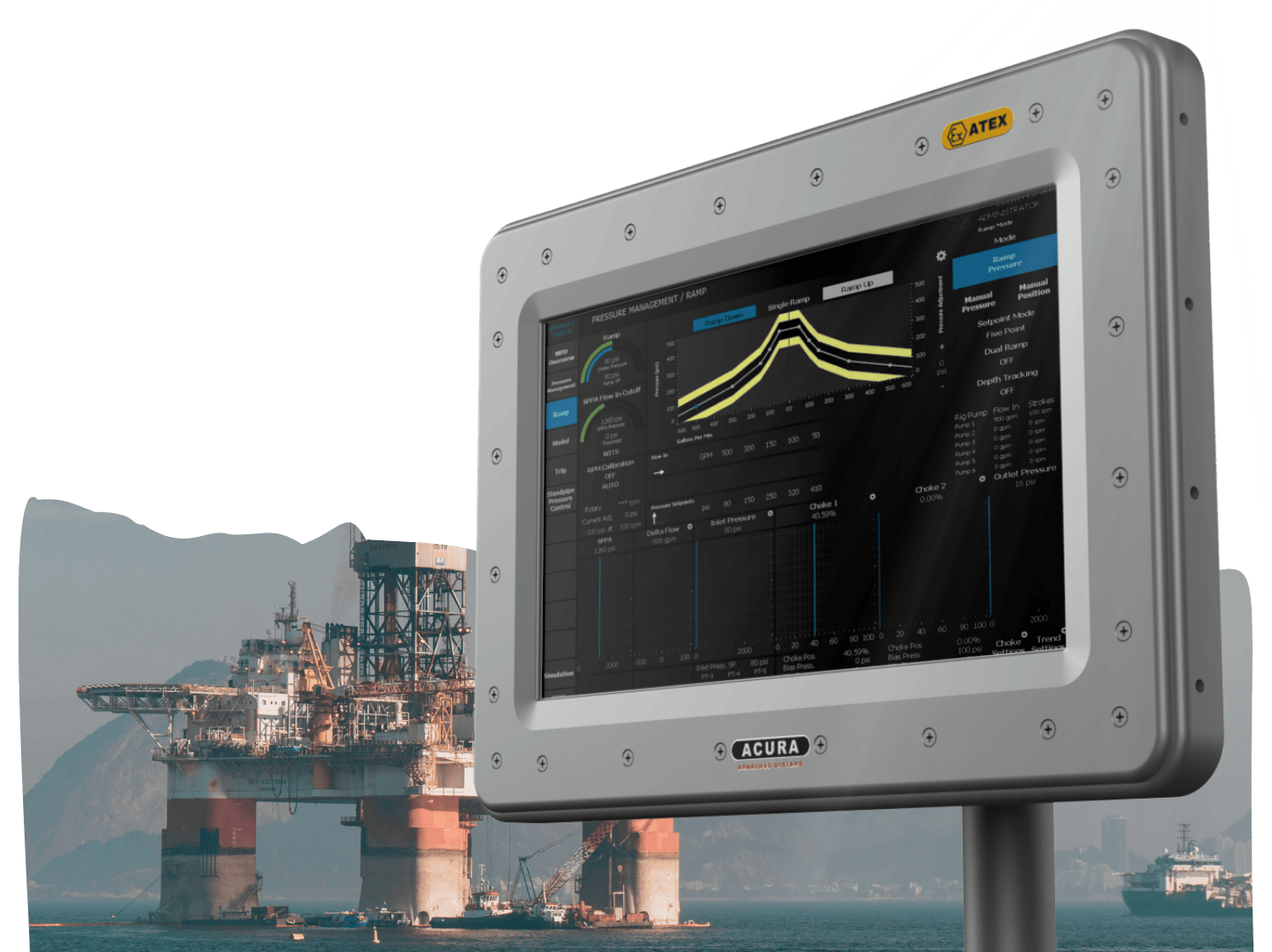

zone 1 hmi - RoughNeck bastion

It's here. The Most Powerful, Lightest-Weight Zone 1 Certified HazLoc HMI in the World.

INTRODUCING A REVOLUTION IN HAZLOC COMPUTING PERFORMANCE

Water Resistant, Dust Proof, Noiseless

Unlocking next-gen performance for extreme environmental conditions. Acura is bringing high-performance CPUs and GPUs to the Edge, embedded in our best of class HazLoc computing hardware.

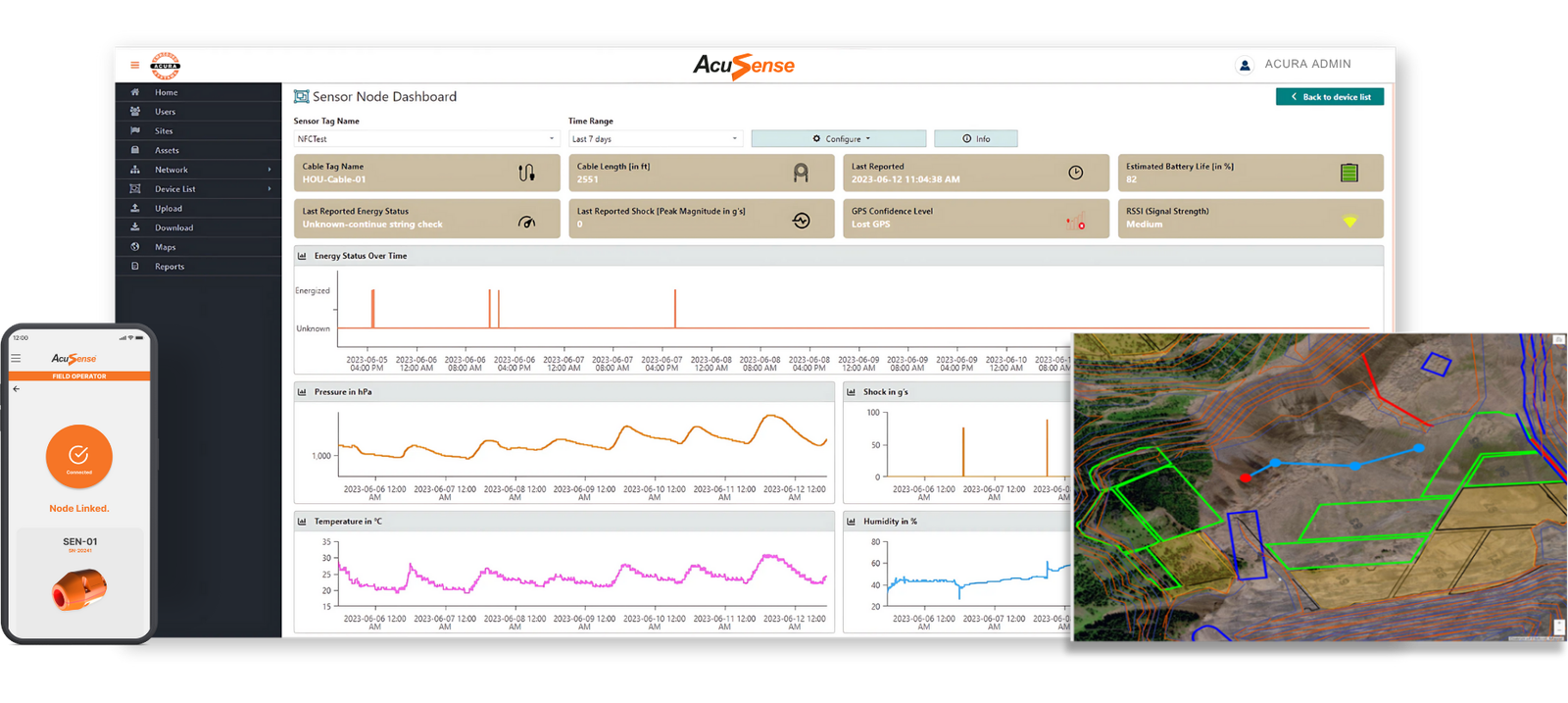

Mining Cable Management SOlution

AcuSense is our revolutionary patented open-pit mining trailing cable management intelligent sensor solution.

PRODUCTS

The Best Performing HAZLOC

Computers in the World.

Our products are designed, built and tested in some of the world's harshest environments. We constantly push the bar for performance HazLoc computing. Built to survive, equipped to thrive.